Is This Yellow Powder the Key to Reducing Global Warming?

A new yellow powder developed at UC Berkeley could revolutionize how we remove carbon dioxide from the air.

The material, named COF-999, works faster than trees at capturing CO2.

The research was published in Nature journal.

"Basically the best material out there for direct air capture," says professor Omar Yaghi about the innovation.

Just half a pound of COF-999 can match a tree's yearly carbon absorption.

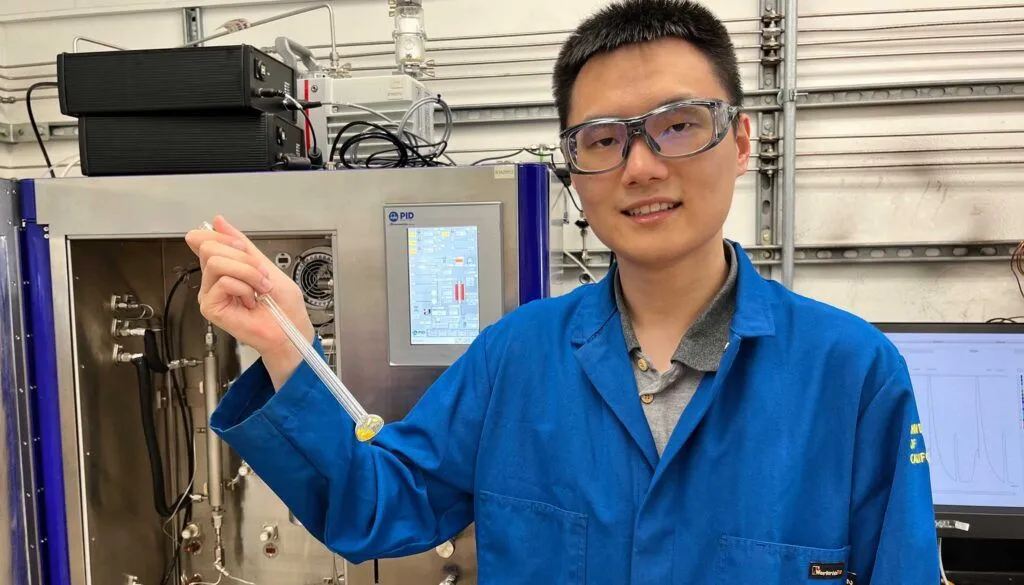

Graduate researcher Zihui Zhou led the project. "In our tests, it cleaned the air entirely of CO2. Everything," Zhou reports.

The powder has survived over 100 test cycles without degrading.

Its structure contains billions of tiny holes, like microscopic basketballs.

Special chemicals called amines help it capture CO2 molecules from the air.

Klaus Lackner from Arizona State University praised the discovery: "They are opening a door into a new family of approaches."

The technology could help keep atmospheric carbon below 450 ppm. Current levels are at 423 ppm.

Direct air capture facilities are already operating in Tracy, California.

"Even if we stop emitting CO2, we still need to take it out of the air," Yaghi emphasizes.

COF-999 works well in humid conditions.

It can pull CO2 directly from regular air.

Jennifer Wilcox from the University of Pennsylvania notes: "It's always exciting when new materials are developed, especially ones that perform well when exposed to water."

The powder releases captured CO2 at 140 degrees Fahrenheit.

This is more efficient than older materials requiring 250 degrees.

Researchers are testing the powder in small columns.

They plan to scale up to industrial-sized metal boxes.

"Team members have continued to make improvements, and we're on track to double its capacity in the next year," Zhou states.

A company called Atoco aims to commercialize COF-999.

The Bakar Institute and King Abdulaziz City for Science and Technology support the project.

Cost reduction remains a challenge for widespread implementation.

The technology could be ready for large-scale use within two years.